Email: info@esttoolsteel.com | Call Us: +91 22 2686 6600

- You are here:

- Home

- Products

- Cold Work Steel

- YTL8

YTL8

Cr 8 Wear Resistant Cold Work Steel

| Chemical Composition | C | Cr | Mo | W | V | Si |

| (Typical analysis %) | 1.00 | 8.50 | 1.70 | 0.50 | 0.90 | 1.00 |

Based on YTL122 (AISI D2), EAST TOOL introduces Cr8 high-carbon cold-work steel, it has a feature of itself in composition and performance and strength and toughness near to high-speed steels.

Property:

- Carbide segregation is the most important quality target of high carbon ledeburitic steel. Both YTL8 and YTL122 belong to ledeburitic steel, but the carbide of YTL8 is finer and the state of distribution is improved thus YTL8 gets the higher toughness and plasticity.

- YTL8 uses the high-heat tempering to replace the low temperature tempering, which reduces residual stresses, decreases the possibility of angle rupture and craze during the patternmaking and improves the security of linear cutting and grinding.

Unique Characteristics:

Higher hardness (62-63 HRc) than D2 after heat treatment.

- Twice the toughness of D2 with superior wear resistance.

- Higher fatigue strength than D2.

- Smaller primary carbides than D2 protect the die from chipping and cracking.

Application:

Mould that can resist grain-abrasion, mixture abrasion and angle of rupture.

- Mechanical blade (Cold shears), Thread rolling Dies, Drawing die

- Forming dies, Piercing punch, Dies for cold forging

Steel Density 7.84 g/cm3

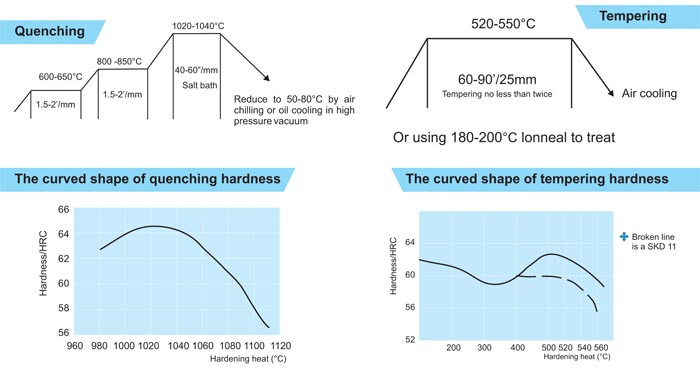

General method of heat treatment